Technical Articles

Submersible pumps play a crucial role in the water management of water systems and agricultural irrigation systems. In most cases, they are situated in an extreme environment where the operations of these pumps are anticipated to take place over long durations. All parts involved in the electrical control system must be fully functional to ensure efficient operation and longevity.

One such critical component is the overload relay, an essential part of the submersible pump motor starter. It prevents possible damage to the pump due to the current circulation. In this blog, let’s understand the workings of an overload relay and its importance.

Submersible pumps can be tricky to reach once installed, as compared to surface-level motors. Damages resulting from electrical faults can lead to high repair costs and significant downtime. Overloading conditions leading to overheating are the most typical causes of pump failure. It is at this point that overload relays are used.

The intended application of an overload relay is to observe the amount of current being used by the pump motor. When it reaches the limit and exceeds this limit within a particular time, the relay de-energises the power to prevent thermal damage to the motor. In the absence of such a safety system, motors would risk damage during long periods of operation, or when blockage prevents non-destructive ways to stop.

An overload relay is a sensing device that detects abnormal current flow and trips the circuit when the motor experiences overload. It does not respond instantly like a fuse or circuit breaker. Instead, it allows temporary current surges during motor start-up but reacts if the excess current persists.

Overload relays are typically installed in the submersible pump motor starter, which houses other critical components like contactors and manual or automatic control systems. The relay works in tandem with the starter to disconnect the motor automatically during overcurrent situations.

There are two major types of overload relays used in motor starters for submersible pumps.

In this variety, a bimetallic strip bends as the additional current flowing through it heats up. When it passes a determined limit, it causes the strip to operate the contact and break the circuit. Thermal relays can be used on the majority of agricultural and domestic pump systems because they are simple and effective.

Digital relays are more accurate at measuring current with sensors. They are programmable and have several features, including options for delay times and reset modes, and fault memory. They find common application in industrial submersible pump motor starters where system complexity is increased and where precision is necessary.

The motor starter for submersible pumps acts as the control centre. The contactor inside it connects and disconnects the motor from the power supply, and the overload relay, which monitors the load itself constantly.

This system guarantees that submersible pumps are never left to run under hazardous conditions, especially when there is no human supervision. Here’s a step-by-step working of the same:

When the pump runs within the specified current limit, the relay does nothing. The motor continues running uninterrupted.

If the motor draws current above the safe range, the relay begins its thermal or electronic response.

If the high current persists, the relay trips the contactor. The motor is disconnected from the power source to prevent overheating.

Depending on the type, the relay either needs a manual reset or will auto-reset once it cools down.

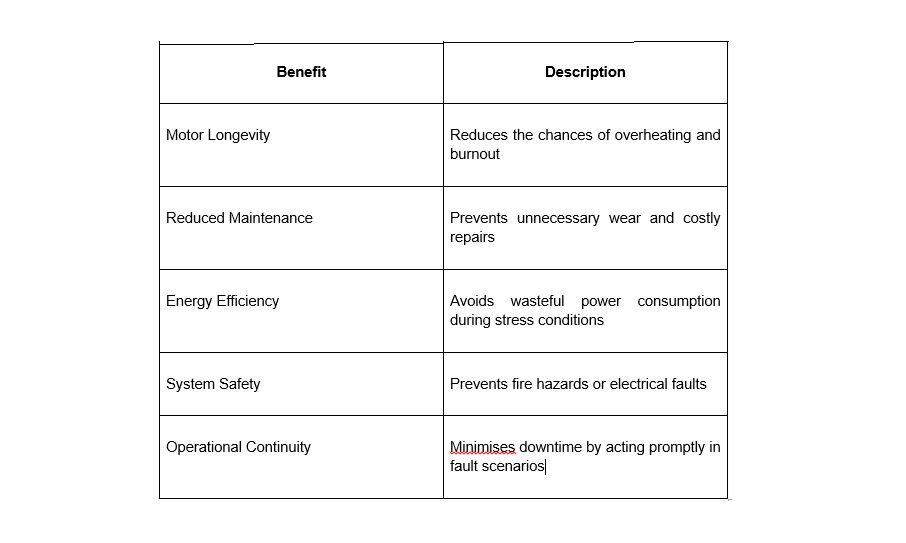

A well-functioning overload relay contributes to the whole system’s overall performance and reliability. The following advantages are why overload relays have become a standard feature in every submersible pump motor starter unit:

Applications that involve the continual use of motors under different levels of loads prove to have a substantial influence on overload relays. They help ensure smooth functioning in the following areas:

In farms, motor starters for submersible pumps often operate unattended. Overload relays ensure the pumps do not continue running when suction is blocked or when voltage drops lead to overcurrent conditions.

In residential buildings, the overload safety in the borewell is extremely important. The motors are small in size, yet easy to overload by sediment or dry running. The overload protection is built into the starter with an overload relay.

These pumps run under heavy load conditions in mining or construction areas. Overload relays help maintain consistent output and reduce maintenance costs in demanding environments.

Following these simple practices can significantly increase the lifespan of both the relay and the submersible pump motor starter. Once installed, overload relays require occasional attention to ensure continued efficiency.

● Test the tripping function every 6 months

● Clean the motor starter enclosure to prevent dust buildup

● Verify that the relay settings match motor specifications after maintenance

● Inspect terminals and tighten connections periodically

Overload relays may not draw attention, but they have a purposeful application in ensuring submersible pumps are safe from current-related damage. Placed inside the motor starter for submersible pumps, these relays help the system operate smoothly, without the need for constant monitoring.

Quick Links

Miniature Circuit Breaker | Air Circuit Breaker | Home Automation Systems | Switches and Sockets | Variable Frequency Drives | Energy Management System | IEC 61439 Panels | Moulded Case Circuit Breakers | AC DRIVE | Submersible Pump Motor Starter | Mobile Starter | Industrial Automation | Residual Current Circuit breaker | APFC controller | Power Factor Correction | Motor Protection Device | Medium Voltage | Vacuum Circuit Breaker | Programmable Logic Controllers | Human Machine Interface | Solar MCCB

Assistance Required?

Select an option to Contact Us